Part 1 – “Why this car matters: The History, Race Results, and Prior Ownership”

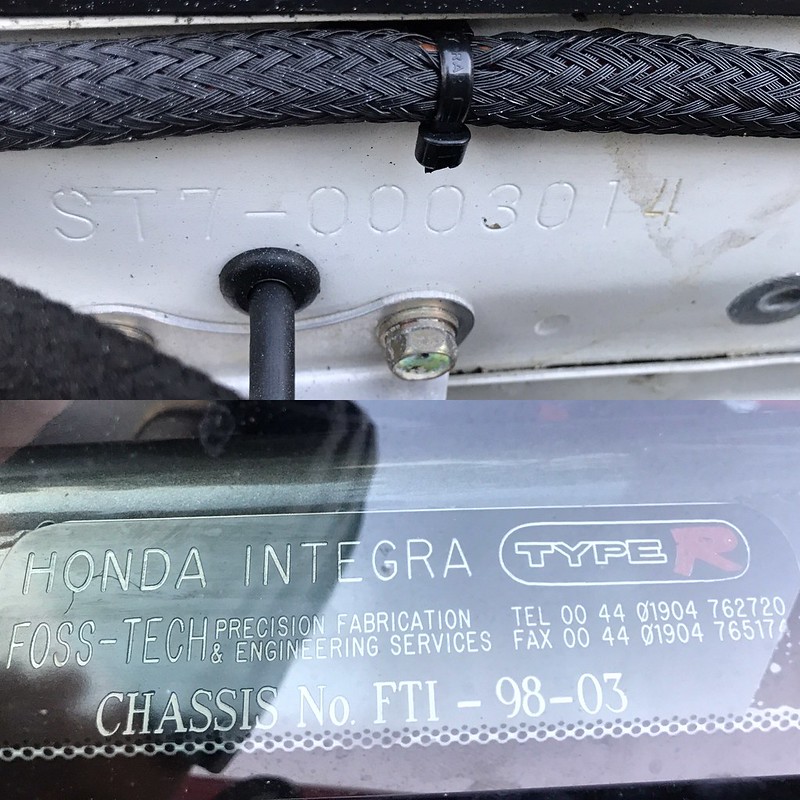

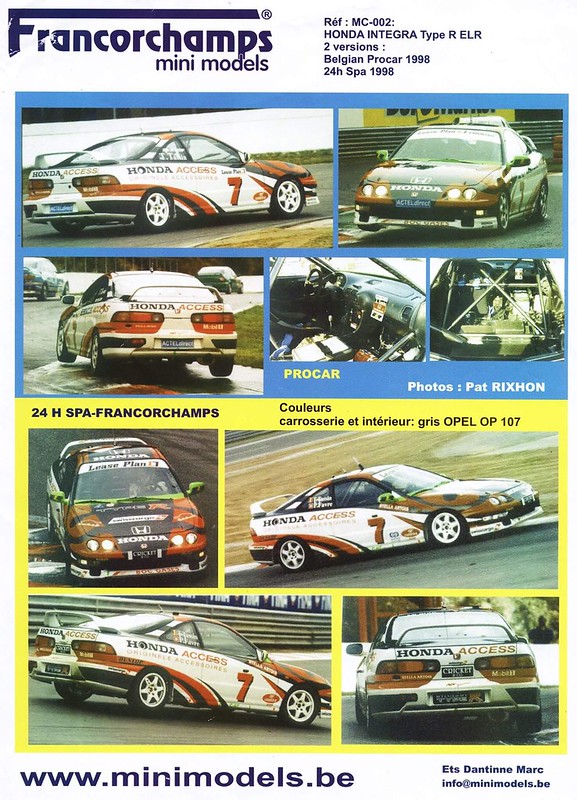

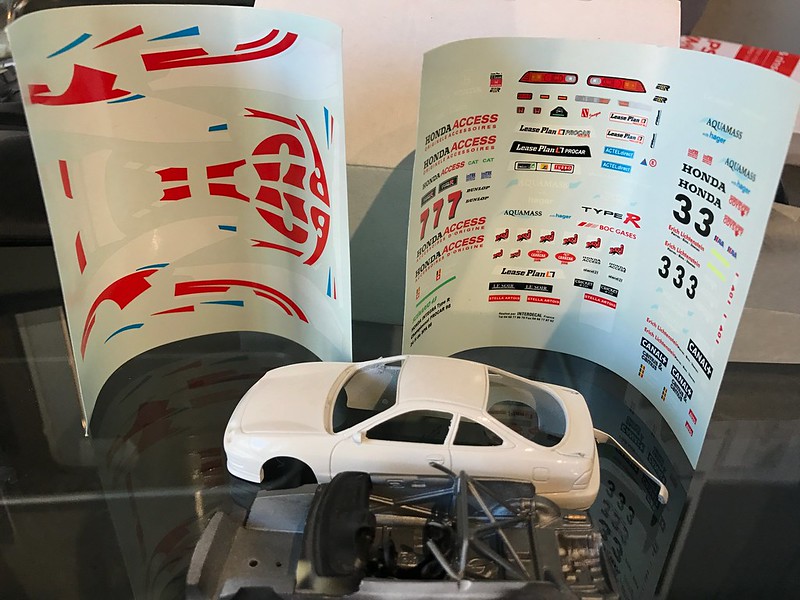

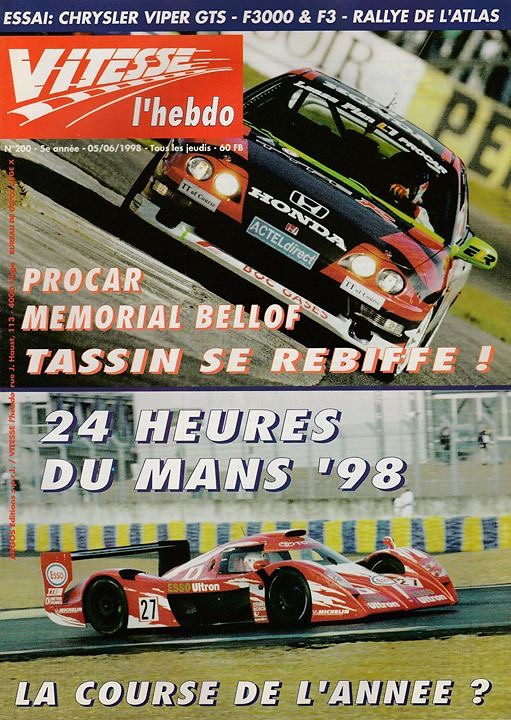

This car was part of a batch of the “Body in White” Integra Type R that was sold directly by Honda Motorsport Europe (Honda Racing Europe) to Foss-Tech (York) Precision Fabrication & Engineering Services Inc. in Harrogate/ North Yorkshire, England, in late 1997 to be prepared for racing purposes under the FIA Super Production specifications for the 1998 Belgian Procar series.

Honda’s “Body In White” program is unique; it gives race teams and chassis fabricators a stripped-down primered vehicle shell that can be modified to exact personal specifications. The chassis is also a lighter platform to start with, as it lacks heavy rust inhibitors (zinc plating), seam sealers, adhesives, sound-deadening material, crash beams, and other items found in a standard production vehicle. This particular car has the Body in White chassis number ST7-0003014. The Realtime Racing cars and a handful of other factory-supported race teams have similar and sequential chassis numbers.

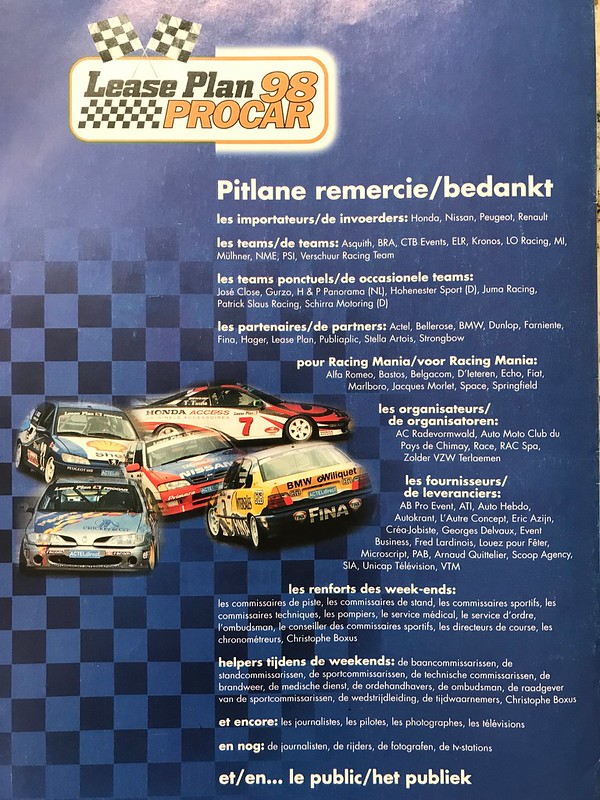

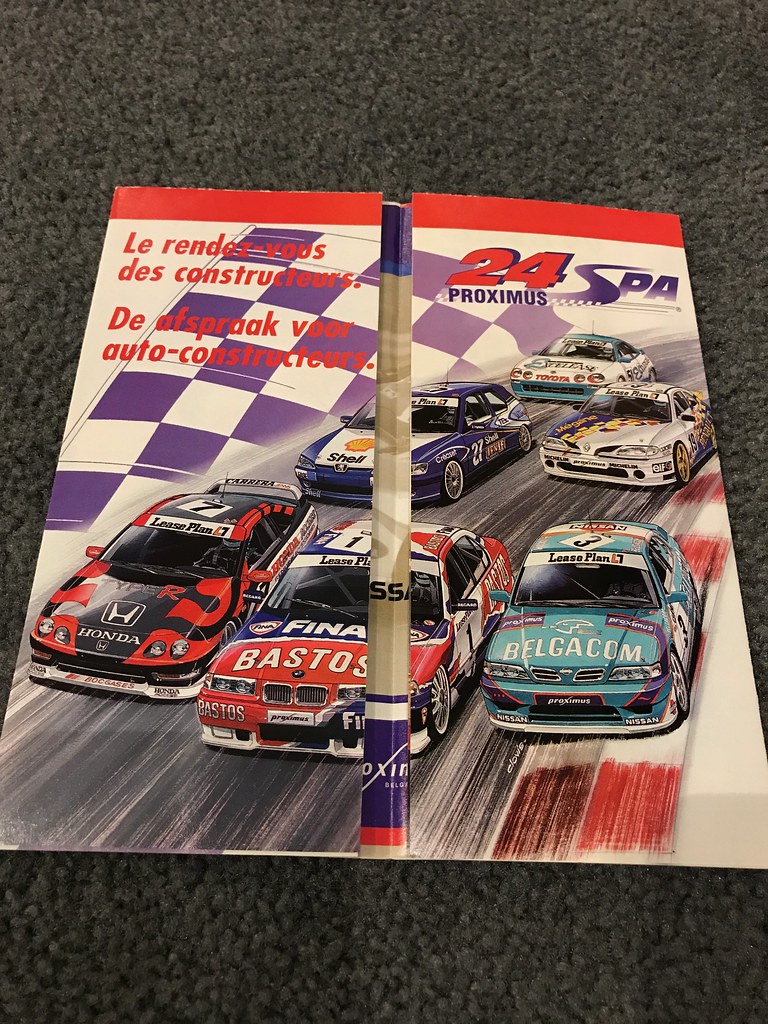

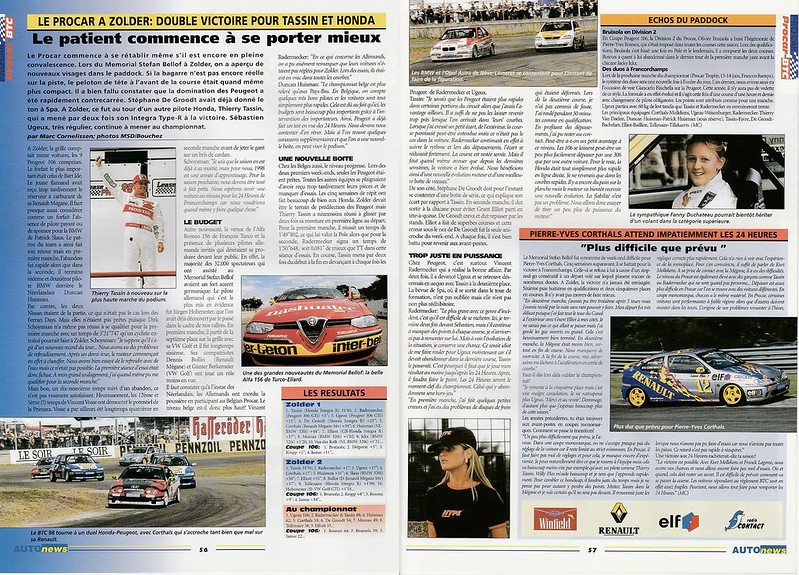

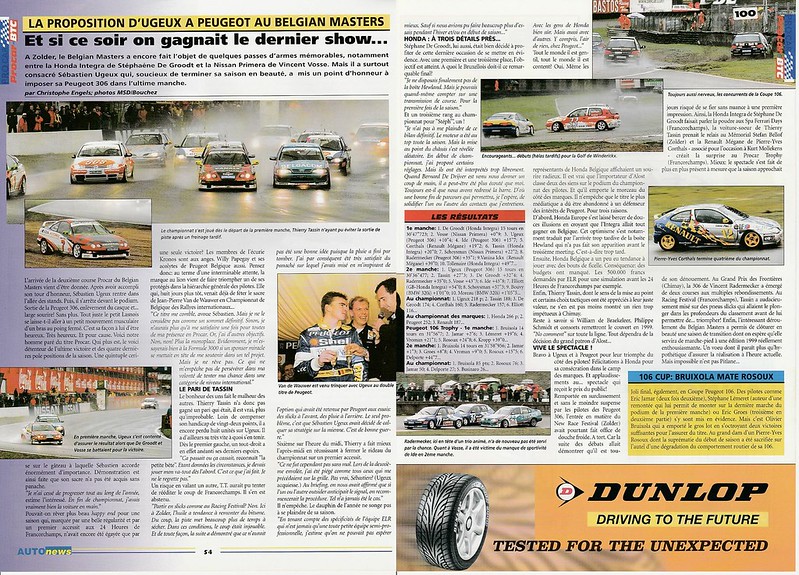

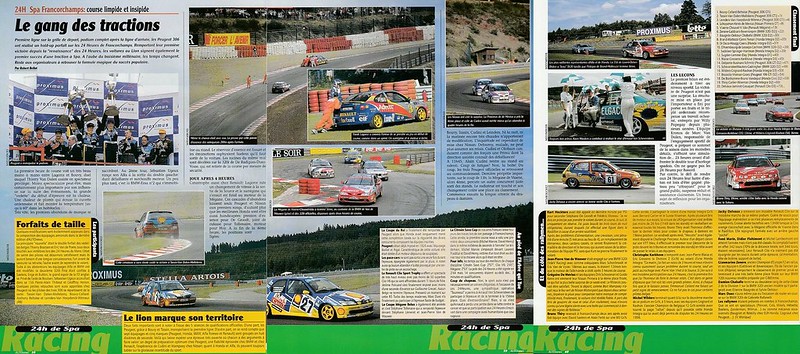

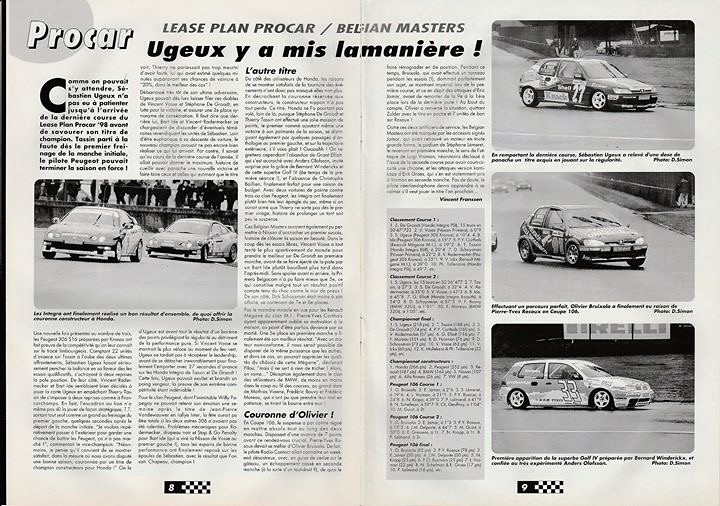

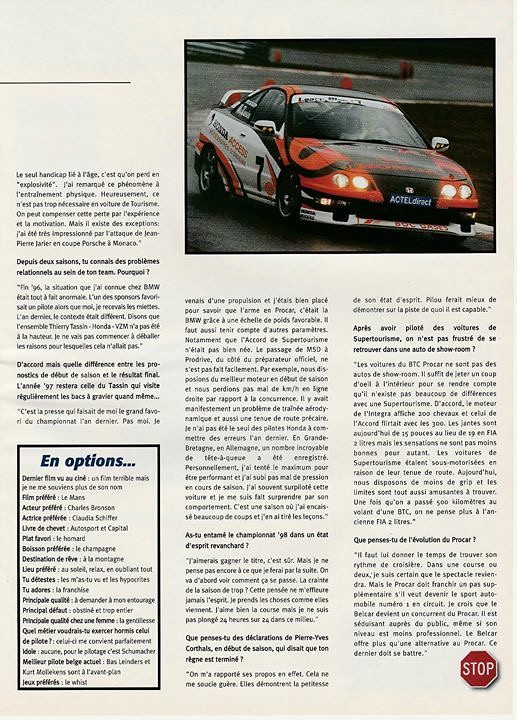

European touring car racing has a long history of competition that draws enormous crowds and sparks manufacturer- and model-specific cult-like followings. Such racing series with the BMW (M3, 320i, E30, E36), Renault (Megane), Peugeot (306), Mercedes (190E), Audi, and VW, to name a few, have produced some of the most iconic models that we’ve come to cherish. Outside of the NSX and Accord, Honda had mostly been absent from the European/FIA Group N specification racing series. However, in light of the 1996–1997 popularity of the Integra Type R in Japan, Honda wanted to introduce the car to the European market in 1998.

To make a major footprint in the European touring car scene, Honda selected the infamous Belgian Procar series, intending to set as many track records as possible and clinch the manufacturers’ (constructors’) championship in 1998. The goal couldn’t have been set higher, but Honda had all the right people in place to make it achievable. This effort was primarily led by William De Braekeleer, Head of Honda Motor Europe, David Thomson of Foss-Tech, and Marc Vanderghen of European Luigi Racing (ELR), along with a handful of other fabrication shops and race teams. Foss-Tech handled the chassis fabrication and ELR the race car setup, engine tuning, and race strategy.

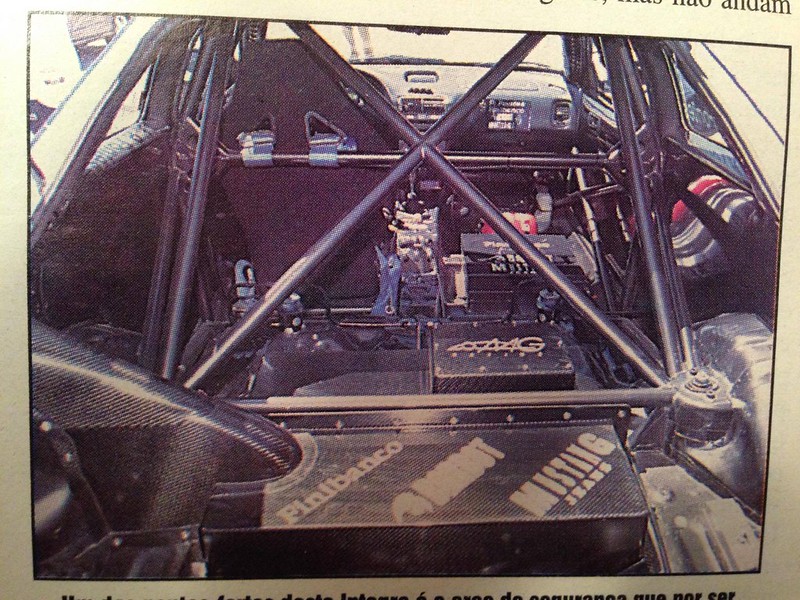

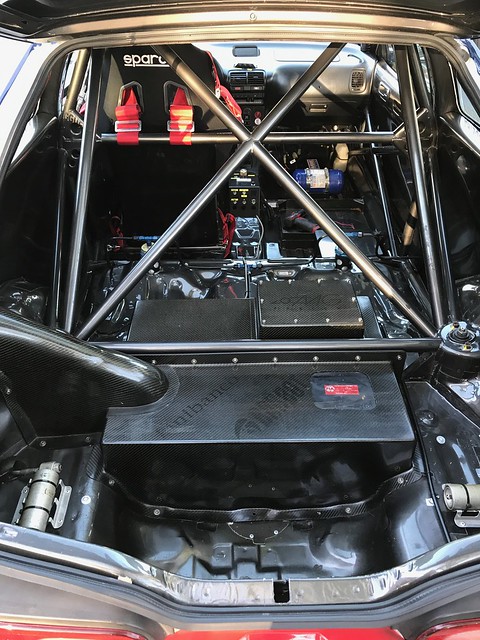

Foss-Tech placed the Body in White chassis on a rotisserie, fully seam welded it inside and out, and built a highly customized roll cage made from T45 steel (similar to chromoly). T45 is a unique and special alloy that has a tensile strength approximately twice that of the standard Cold Drawn Seamless (CDS; aka mild steel), meaning that the roll cage could be built with tubing of the same diameter but of a thinner gauge (wall thickness) for additional weight reduction. This equates to a weight savings of approximately 1/3 pound per foot of tubing, or 10–15% of the total roll cage weight, when compared to CDS. T45 is typically used in aerospace and high-end racing applications because of its high cost, scarcity, and demand for specific preparation and welding techniques. The multipoint roll cage features a custom rear strut tower and wheel well reinforcements, center subframe brace, rocker sill bars, driver seat support, gusseted door impact X-braces, six-point dash/firewall bracing, and a three-point front strut tower triangulation. Nearly every weld point is gusseted and attached to the body where possible. The cage also incorporates four-point air jacks, fuel cell supports, and attachment points for the dash, rearview mirror, and other accessories.

Foss-Tech also modified the rear suspension pick-up points for a better roll center, boxed the rear trailing arms, rear upper and lower arms, and rear toe links, and replaced all bushings with custom offset spherical versions to increase camber to upwards of -5 degrees and caster by +2 degrees. For the anti-roll bars, Foss-Tech fabricated a three-piece system for the rear that can attach to either the lower arm (factory style) or the trailing arm (near the upper arm connection point) for increased effectiveness. For the front, they created a three-piece system that mounts to the lower subframe and connects to the lower arms in a similar manner to the factory setup. The two systems are fully adjustable, with three stiffness settings, interchangeable hollow and solid main bars, and tubular or blade-style arms. For the actual suspension, Foss-Tech equipped the car with a three-way Penske setup that uses external reservoirs on each corner and features unique mounting hats to maximize the pivot angle and decrease suspension/coil bind. Because of the modified roll center, it was possible to utilize softer springs to increase overall stability.

Custom-fabricated four-point AP Racing front brakes were equipped with custom carbon fiber ducting to cool the caliper and pads, rotor and hat, and outer CV joint. The transmission and inner CV joints also feature custom carbon fiber ducting for additional cooling. The car has lightweight 15x7 magnesium Technomagnesio Racing Competition wheels; the current tires are 19/57-15 Michelin Circuit GT/Sedan racing slicks, compound - S8B - medium. Originally, the tires used during the Belgian Procar series and the 24 hours of Spa were Dunlop SP Sport racing slicks, sizes 185/580R15 and 200/580R15.

Foss-Tech’s carbon fiber ability was top notch; they used the very best aerospace- and F1-derived processes to ensure maximum strength and lightness as well as entirely vacuum-bagged pre-impregnated carbon that was cured in autoclaves. The strength-to-weight ratio they achieved is phenomenal. The chassis was equipped with carbon fiber door cards, rear quarter panel covers, a driver side Nomex honeycomb carbon fiber side impact X-brace cover, a carbon fiber center console switch panel, a radio delete switch panel, center console side covers, steering rack cover, air vent covers, and, most notably, the brake ducts, bumper ducts, transmission duct, fuel cell containment box, radiator and oil cooler ducting, battery cover, and rocker sill covers.

The engine cooling is managed by a surprisingly small (half-size) radiator that is aided by sizeable carbon fiber ducting in the front bumper that routes air to the radiator, the air-to-air oil cooler, transmission, brakes, and air box intake plenum. The fuel system features an elaborate FIA-FT3 bladder-type fuel cell that was designed by Premier Fuel Systems and enclosed in a custom-molded carbon fiber casing. Depending on the race, the fuel system can be adjusted to a single 55L cell (under the car) and/or a 45L cell (inside the car). For endurance events, the car can run both cells, for a combined total of 100L (the FIA limit) and use a larger expandable carbon fiber containment case and dual fuel pumps.

In terms of electronics, an MBE Systems ECU and a custom-made engine harness controls the motor. The system uses a modified OBDI distributor as a camshaft sensor and ignition spark rotor as well as a special crank position sensor built from a modified Type R crank pulley. The ECU and an external Bosch module handle the ignition. Data-logging is carried out by the MBE ECU, and driver feedback is provided through a Stack 8100 dash system with a built-in rear wheel speed sensor, lap beacon, and various engine sensors (oil temp, oil pressure, fuel pressure, water temp). Lastly, an advanced Armtech battery isolation system, Motorola two-way radio system, and electronic fire suppression were also installed.

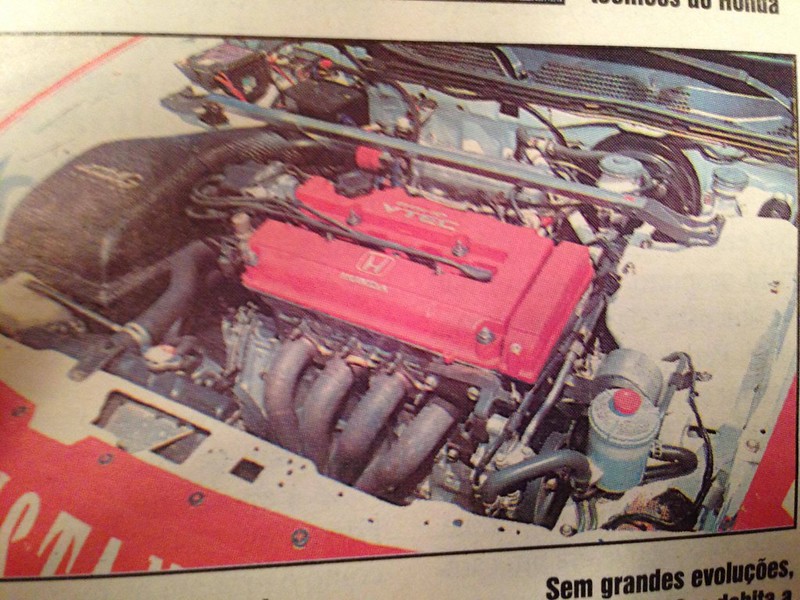

The engine and transmission did not come with the chassis; Honda Racing Europe supplied special B18C6 motors and a custom-developed Hewland, Brena & WTI dog-gear transmission. The motor is mostly stock but was partially developed in a collaboration between Honda, Mugen, Neil Brown Racing, and ELR specifically for Honda Motors Europe. FIA rules strictly regulated the engine and engine equipment variances, so everything was built to maximum tolerances and efficiency. Displacement for the 1998 season was 1.8L, and the power output was in the 210–220 whp range with a 10,000 rpm redline. The motor is distinguishable by a “Procar” engraving on the block and has custom-machined aluminum block-offs on various emissions control systems. Interestingly, the C6 block currently in the car is one of the lowest numbers I’ve seen for any Honda motor (B18C6 - Procar 1 - 0100017). In addition, and unlike in most race cars, power steering was retained but modified for racing purposes to help minimize driver fatigue during endurance races and enhance the dynamics and rapid turn-in of the chassis.

The exhaust is a custom setup designed by Mugen, Neil Brown Racing, PSI Motorsports, ELR, and Foss-Tech. It features a 4-2-1 design, a large 2.5” collector, and a thin-walled 3” exhaust with a large stainless muffler and resonated exhaust tip. Depending on the race regulations (for example, the 24-hour Spa Francorchamps), a special high-flow catalyst would be utilized that was easily installed near the factory location. Its use and location was identified by special markings on the exterior side panels for flag marshals and race personnel. Lastly, as part of the air induction system, the air intake system was designed by ELR; it features a large carbon fiber air box equipped with a panel-style air filter and an oval velocity stack located in the front bumper opening. At Spa Francorchamps, positive air pressure was seen at over 130 mph on the Kemmel straight.

The Hewland/ Brena / WTI transmission features custom gears and final drive ratios (these varied by the racetrack but were within the FIA 2% variant tolerance), custom forks, reinforced shift selector, modified shift linkage, and a custom Hewland/Brenda/WTI Powerflow 1.5-way LSD (clutch style). The clutch is an AP Racing metallic racing design with an AP Racing short-throw master cylinder. The driver seat and six-point harness was originally sourced from OMP (King model), but the car currently has Sparco and Schroth parts installed. The steering wheel is from Alpha, and various safety bits come from SPA Techniques and Stand 21.

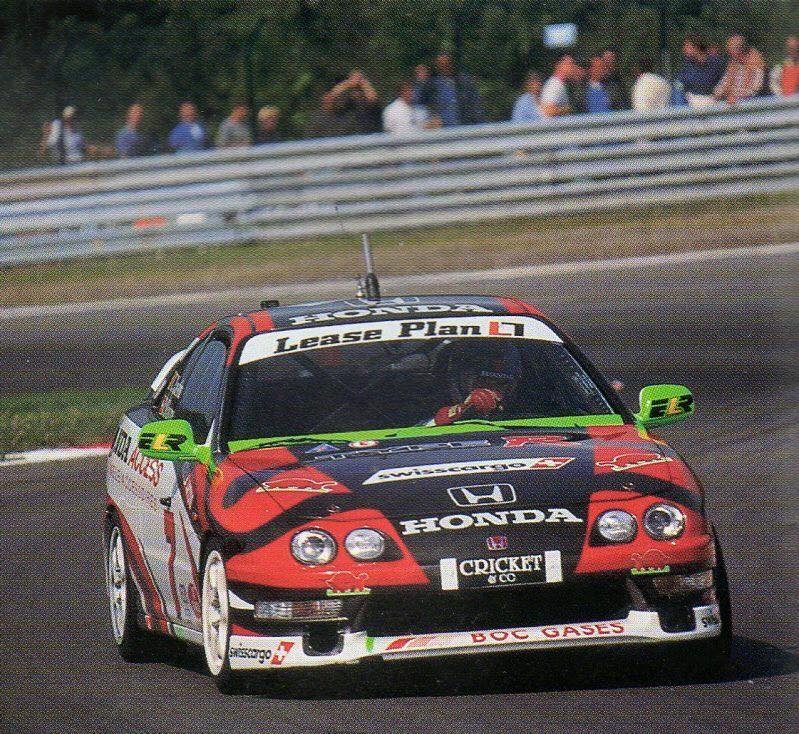

A telltale Foss-Tech feature is a dark metallic gray interior, white exterior, and hand-engraved plaque located on the driver side A-pillar that displays the Foss-Tech serial number. For this car, it’s FTI-98-03. The original white, red, and metallic gray livery was designed by Belgian motorsport artist Jean-Luc Vanuf for Honda Motors Europe and featured prominently in advertising material. The livery was subsequently repainted to white, dark blue, red, and green (the colors of the Portuguese flag) when it raced in Portugal in 1999 and 2000.

Amazingly, while the car came in at a scant 2100 lbs, it still has many accessories, such as wipers, modified windshield wiper cleaners, full OE glass, full OE metal body panels, heater/blower, headlights (low/high), turn signals with side markers, parking lights, brake lights, rear fog light, full exhaust, oversized 40-lb battery, ballast box, and power mirrors, windows, and steering.

Due to FIA rules in 1998, the aerodynamics had to remain mostly stock; however, Honda Motor Europe was able to make some crucial changes to the 1998 chassis to better comply with the rule limitations. For example, the FIA rules say brake cooling ducts can be added in factory lighting locations (i.e., fog lights), but essential lighting equipment (headlights, turn signals, parking lights) cannot be removed. The EDM/UKDM fog light locations were specifically designed to be used as a brake cooling ducts for racing purposes under FIA rules. Some people claim the Type R is mostly hype and marketing material, but a great deal of the special equipment goes unnoticed. These modifications tie directly back into FIA Group N and Super Production rules, especially for the 1998+ US/EDM/UKDM models.

Individuals that were directly involved with this race program reported that the Foss-Tech/ELR/Honda cars cost well north of $125K and ran over $250K with the addition of the spare Hewland/Brena/WTI transmissions, Honda Racing engines, magnesium racing wheels/racing slicks, and various suspension and fuel setups for each track. To say these cars were built with no expense spared would be an understatement. Honda knew that competitive racing in Europe was a must-win situation, both financially and to prove themselves in the touring car segment.

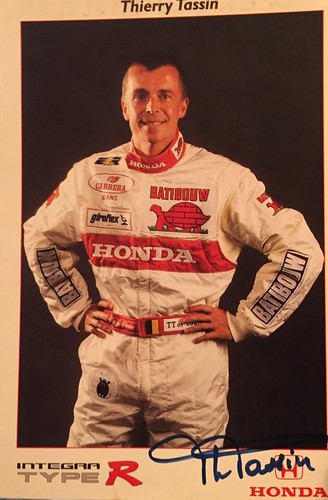

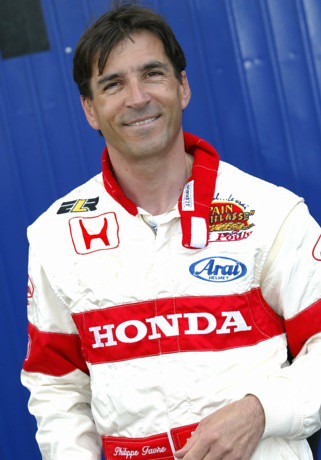

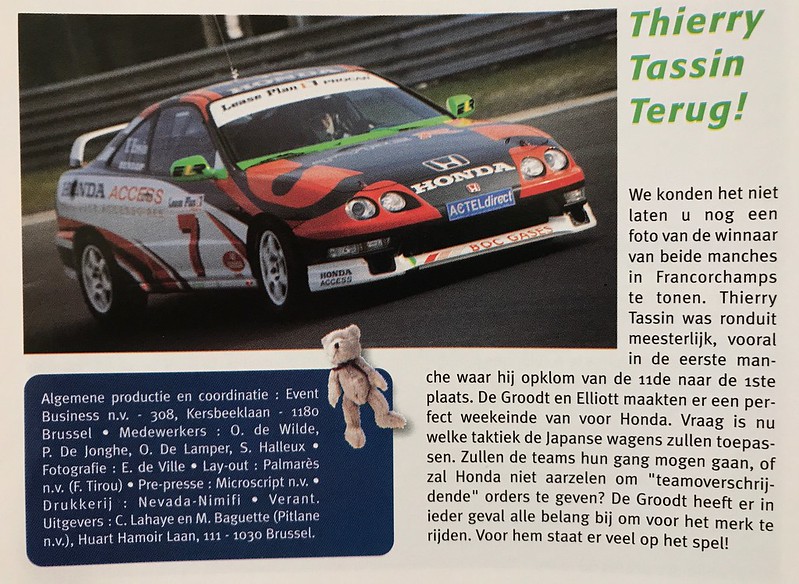

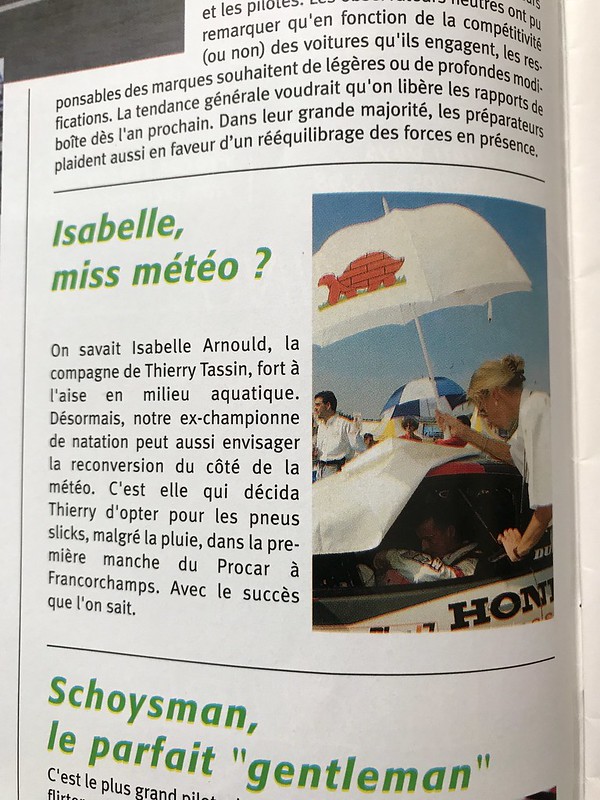

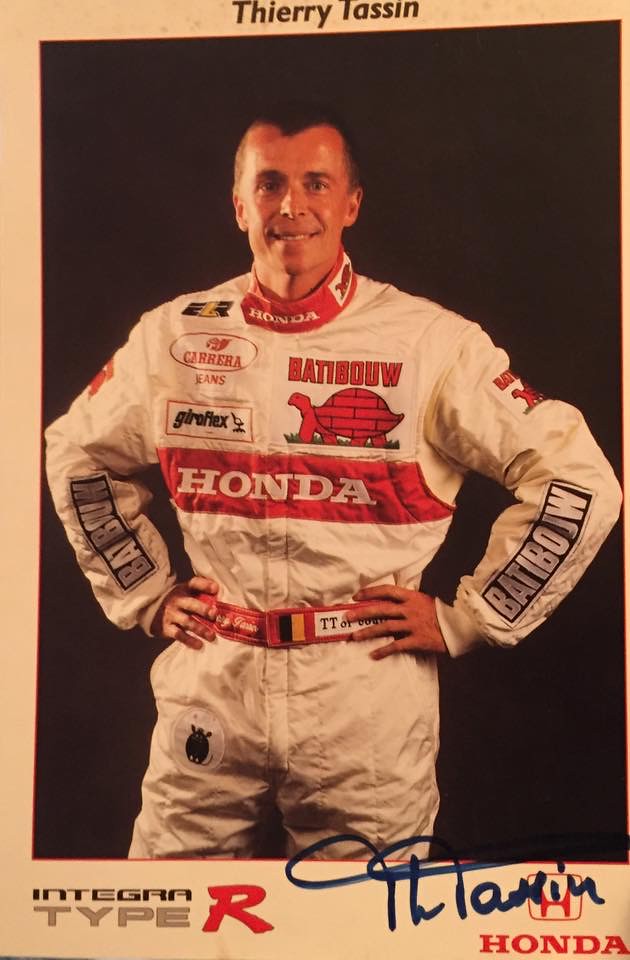

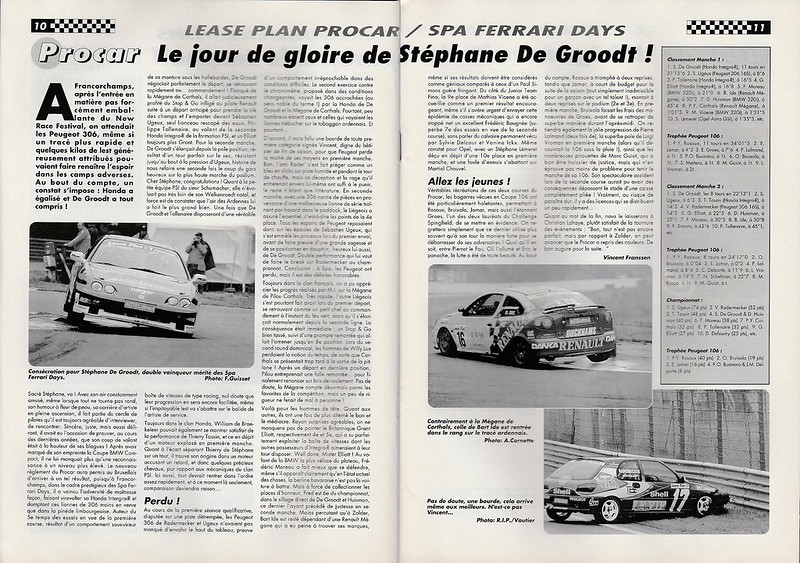

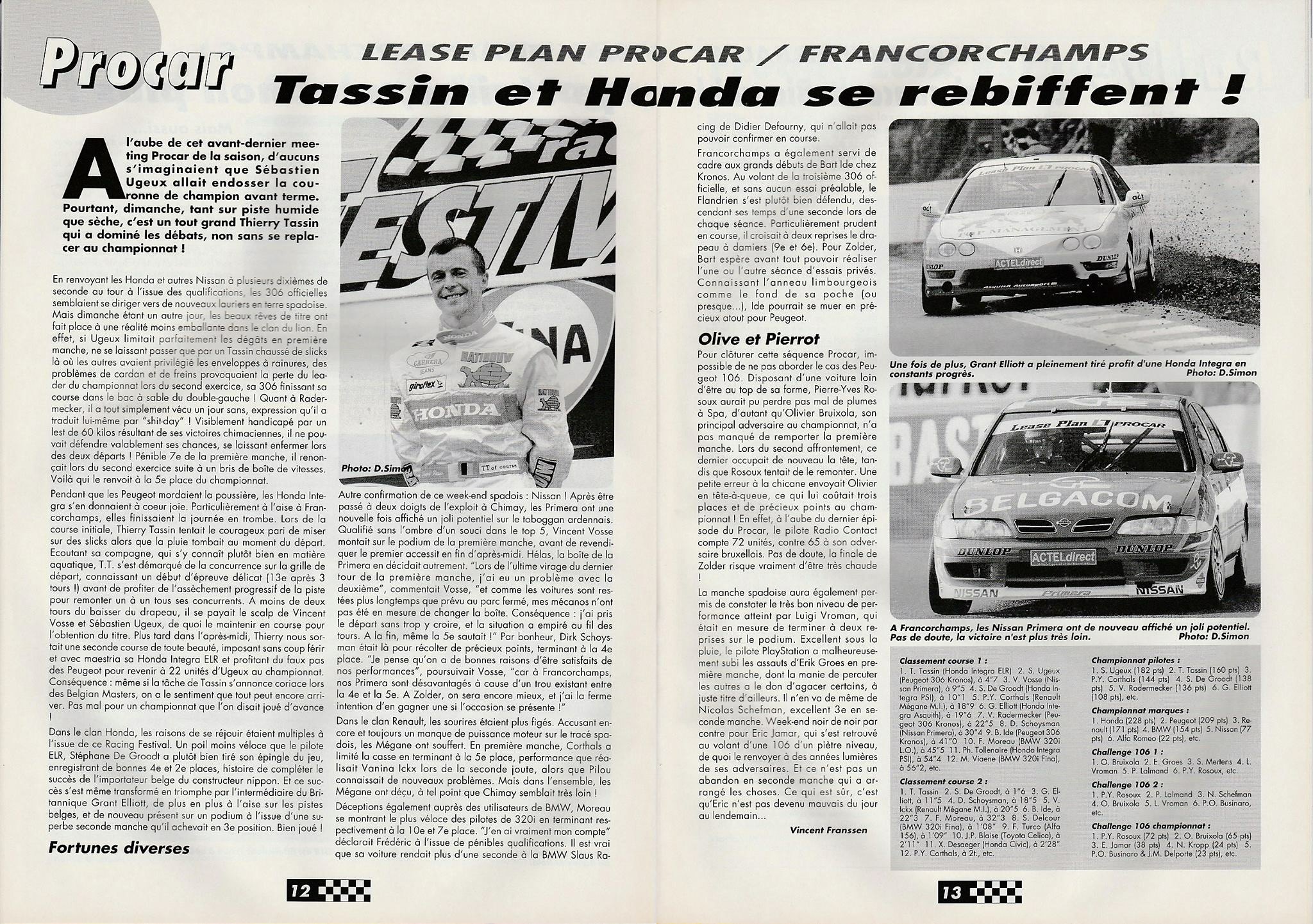

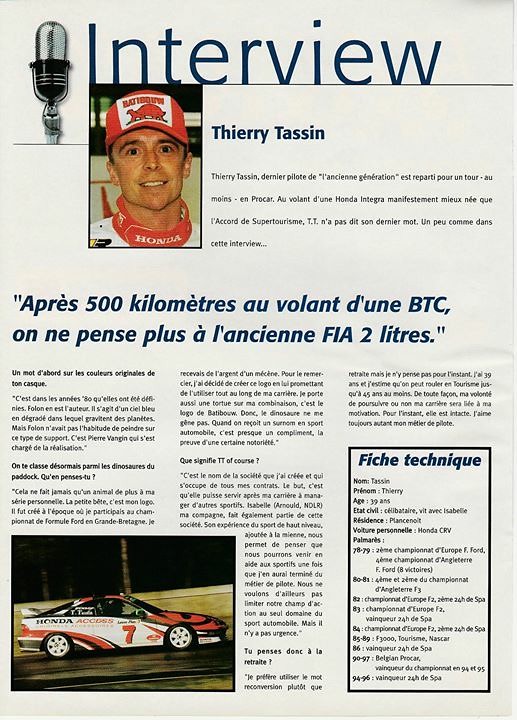

Foss-Tech was also the official race team for Honda under the Honda Sport Belgium—Honda Access Accessories livery. Four-time Belgian Procar/European Endurance champion Thierry Tassin was the primary driver, and Philippe Favre served as a codriver for endurance events. Tassin is most noted for his time racing the BMW 6 series under the Bastos livery in the early 80s, the Ford Sierra RS Cosworth in the late 80s, the BMW E30 M3 Sport Evo and E36 320i under the FINA/Bastos livery in the early 90s, and the Stella Artois/Mobil 1 (Team VZM) Honda Accord in 1997. Philippe Favre was primarily known for his time in the F3000 series and driving under the Kenwood and Maxell livery for Kremer Racing NSX GT1 & GT2 cars in the 1994 and 1995 24-hour Le Mans.

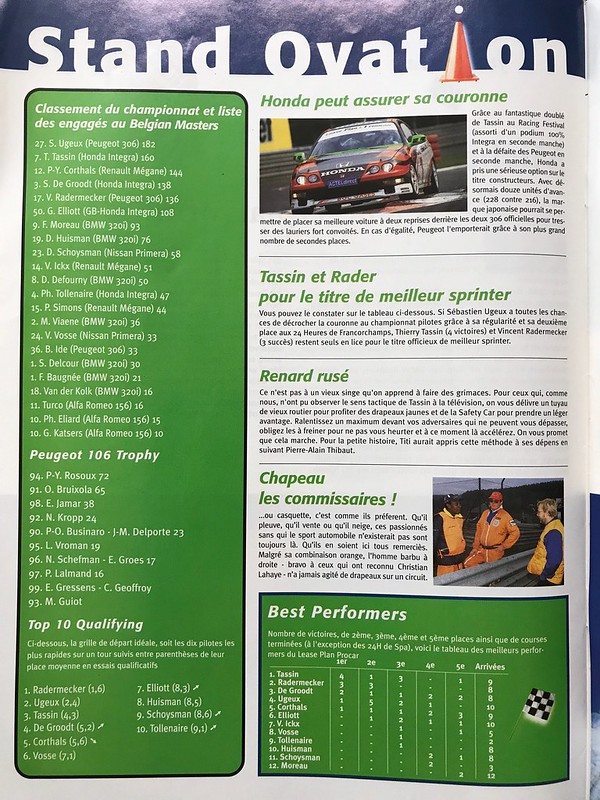

In 1998, the car competed in 14 races and achieved 4 wins, 8 podiums, 1 pole position, and 6 fastest laps (including several track records). It finished with 188 points, was runner-up in the drivers’ championship, and helped Honda clinch the Manufacturers’ World Championship. It was also awarded the prestigious Coupe du Roi trophy in the 1998 24-hour Spa Francorchamps after leading the race for almost 17 hours straight. The trophy, given to the most consistent car, is one of the oldest awards in motorsports.

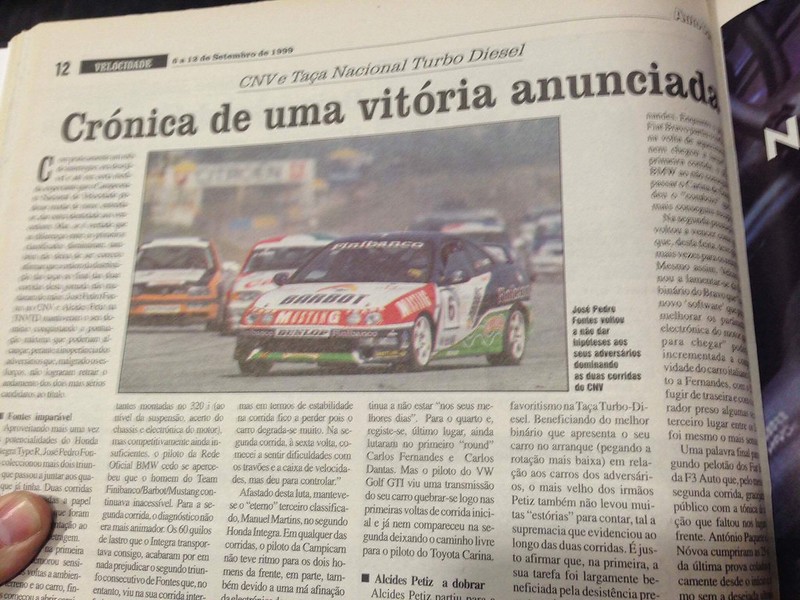

In 1999, ELR sold the car to José Pedro Fontes, the reigning Portuguese rally champion. He raced it in the Portuguese Touring Car Series (Campeonato Nacional de Velocidade) and won the championship that same year. In 2000, he competed in one more race (which he won) before retiring the car to focus solely on rally racing. While the livery was changed, the car’s equipment and setup remained original. In fact, Mr. Fontes would frequently fly ELR to Portugal to inspect and prepare the car for races.

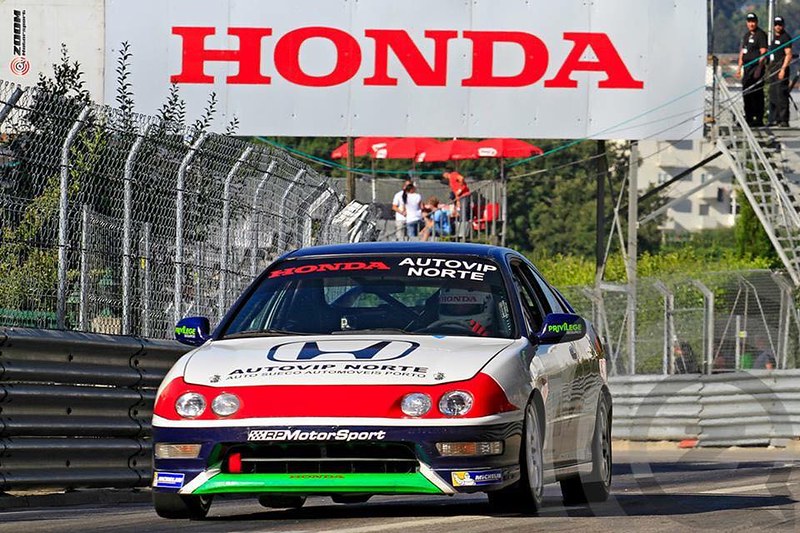

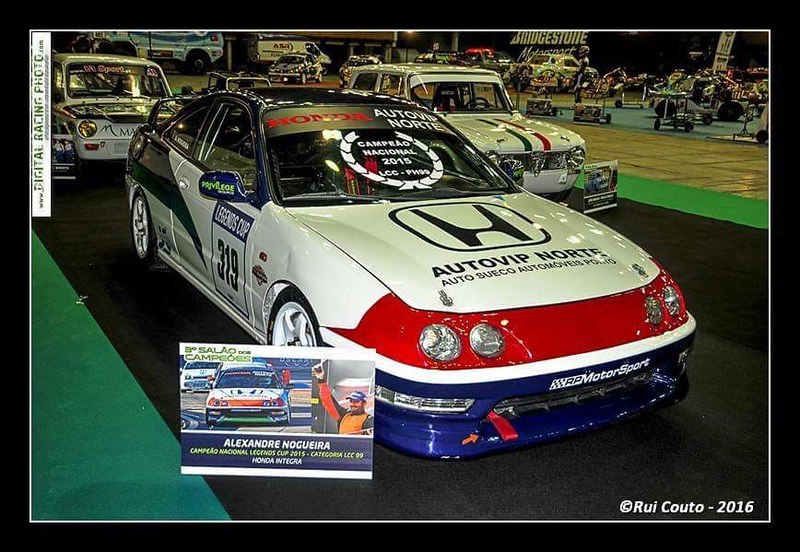

In December 2014, after 14 years in storage, the car was sold to Alexandre Nogueira (Portugal) who competed in the 2015 Portuguese Historic/Legend series (Campeonato Nacional Legends Cup) and won the championship that year. In 2016, he competed in two more Legends Cup events and won both before the car was retired yet again.

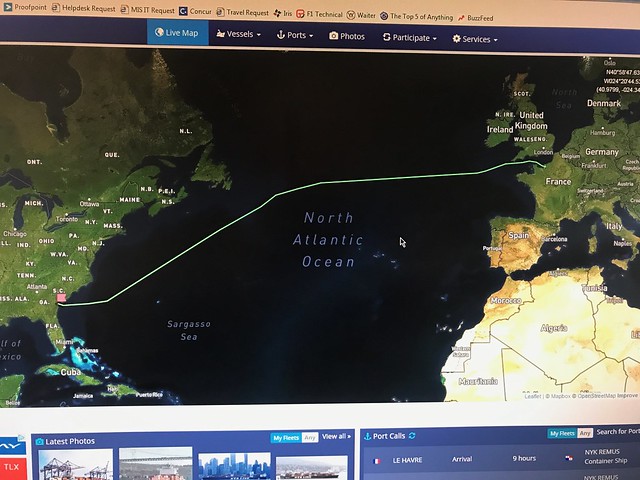

In 2017, I purchased the car from Alexandre with the intention of importing it to the USA so I could restore it to its original Belgian Procar livery, thoroughly document its history, and enjoy it at local open track day events and historic racing series. I had been in communication with Alexandre since shortly after he acquired the car, as I was restoring the yellow race car at the same time. My research into the yellow car made me a somewhat of an expert on the Integra Type R's involvement in the 24-hour Spa Francorchamps, the Belgian Procar series, and various European race teams and race series. Foss-Tech, ELR, the 1998–2000 24-hour Spa Francorchamps, and the 1998–2000 Belgian Procar series became my specialty. While I wasn't in the market for another race car, I knew it had to go to a good home, and I realized I couldn't live with myself if it slipped through my hands. After a few weeks of negotiation, we agreed on the particulars, and the car was loaded into a container bound for the USA.

I’ve spent a significant amount of time gathering historical racing memorabilia on this car and communicating with those that were involved in its racing history, including William at Honda Motor Europe, Marc at ELR, and various photographers and journalists.

Importation of the car was complex and challenging; I received a Racing Exclusion letter from the EPA, approval for Box 8 exemption status on the SH-7 form from the NHSTA/DOT, and special Customs clearance via a clearing house broker. I also had to get an email and letter from Honda as well as several emails and letters from ELR authenticating its history, ownership, and pedigree.

Interesting FIA Super Production & Group N rules tidbits and impact on the development of the Integra Type R:

- Per FIA rules, “The original apertures in the bodywork (e.g. for fog lamps) may be used for the passage of the cooling air. The connection of the air lines to the original apertures in the bodywork is free as long as these apertures remain unchanged”... “The original lighting system must be retained, with the exception of the fog lamps, and must be operational at all times during a meeting. The headlights must have a road homologation for all countries (ECE, DOT, etc.). The fog lamps may be removed for the passage of the cooling air.” This is why the EDM/UKDM cars have optional fog lights in the bumper rather then in the radiator opening like USDM cars. If you look closely, all Honda/Acura 98+ bumpers have casting marks outlining where to cut the bumper for the fog lights (even USDM cars). The location is critical as it perfectly lines-up with the brakes making it ideal placement for brake ducting rather then taking up space in the radiator bumper opening which would interfere with cooling, air-to-air oil coolers and would require cutting of the radiator support structure. This is also why the factory bumper lights (or headlights/high beams) were never used for cooling as the FIA required they be retained and functional.

- FIA Super Production rules stated that “at least 2500 fully identical units must have been produced in 12 consecutive months and homologated by the FIA in Production Cars (Group N).” I need to speak with my contact at Honda who worked directly with the FIA on Homologating the Type R, however, I’m not sure how Honda got around the 2500 fully identical unit requirement unless they referenced JDM production numbers even though those cars had a different setup then the UKDM/EDM models.

- The reason for all the (interior) carbon fiber panels were because of rules. Per the FIA, “Neither the front and rear door panels nor the rear side panels may be removed. These may be the original ones or be made from metal sheeting at least 0.5 mm thick, from carbon fibre at least 1 mm thick or from another solid and non-combustible material at least 2 mm thick. The panels must totally cover the door, its handles, locks and window winding mechanisms.”

- The EDM/UKDM used unique 15” wheels to meet FIA requirements. Super Production was limited to 15x7 and Group N were limited to the manufacture homologated specifications. Per the FIA, “The wheels are free, respecting the homologated diameter, and the homologated width which is considered as a maximum.” From a gearing, performance and racing slick perspective, the 16” JDM wheel wouldn’t be possible. I’m not 100% sure why they didn’t run the Civic EK9 Type R / USDM Type R wheels, but I’m guessing it was for aftermarket brake caliper clearance reasons. Group N had to use factory brakes but in Super Production, AP Racing and Alcon were the standard units being used. JDM calipers (Spoon) were very uncommon due to poor performance from being limited to factory rotor diameters and thickness.

- Speaking of wheels, the EDM/UKDM cars also used JDM gearing. Coupled with 15” wheels this provided the best performance possible under the FIA homologation.

Ownership History

Late 1997- early 1998: Honda Japan / Honda Motor Europe - as a bare "body in white" chassis

Early 1998: Foss-Tech (York) Precision Fabrication & Engineering Services Inc. - Harrogate/ North Yorkshire England

Early 1998 - late 1998: ELR (Marc Vanderghen) - Belgium

Late 1999 - late 2014: José Pedro Fontes - Portugal

Late 2014 - April 2017: Alexandre Nogueira - Portugal

April 2017 - present: Mike Marsey (me) - California, USA

Driver History

Thierry Tassin

Three time Procar champion ('93, '94, '95), Four time winner of the 24-hours of Spa ('83, '86, '94, '96) and 1 time winner of the French Trophy Touring Endurance series ('11).

Driver Racing Highlights

2011: 1st French Trophy Touring Endurance - Trophy 1

2010: 3rd French Trophy Touring Endurance - Trophy 1

1999: 3rd Belgian Procar

1998: 2nd Belgian Procar

1995: 1st Belgian Procar

1994: 1st Belgian Procar Touring Car Championship

1993: 1st Belgian Procar Touring Car Championship Class B

1992: 2nd Belgian Procar Touring Car Championship

1981: 2nd Marlboro British F3 Championship

Racing career summary

Races entered: 202

Wins: 44

Podiums: 97

Pole positions: 12

Fastest laps: 23

Race win percentage: 21.8%

Podium percentage: 48%

Seasons Racing this Car:

1 - 1998 Belgian Procar Championship (14 races)

Result: 2nd place in the championship w/4 wins, 8 podiums, 1 pole position & 6 fastest race laps. Won the Manufacture Championship for Honda.

1 - 1998 24hrs of Spa Francorchamps

Result: DNF due to engine issues

Qualified: 5th place

Miscellaneous Stats:

- Was odds favorite to win

- Held the fastest lap of the race

- Lead the race for 9 of the first 24hrs, the motor failed at hour 16 of 24 (8hrs remaining)

Philippe Favre

Unfortunately killed in a skiing accident in 2013

Philippe Favre (CH-Swiss) spent his racing career driving in Formula Ford, Formula 3, Formula 3000 before being signed as a driver at Kremer Racing in the sports car ranks.

His career brought him to Le Mans on multiple occasions in a GT1 and GT2 Honda NSX, and spent much of the remainder of his time in sports cars, in a Lucchini SR2 in FIA Sportscar racing.

From 2003-2005 he competed in the Le Mans Endurance Racing series with Christophe Ricard.

Favre built a track day company in 2002, assisting numerous drivers learn the sport, including current endurance driver Henri Moser.

He started racing in French Formula Ford 1600 in 1984 after a short karting career and shifted over to Britain to continue in FF1600 the following season.

A second year in Britain in 1986 yielded the runner-up spot in both the RAC FF1600 championship and the prestigious end-of-season Formula Ford Festival at Brands Hatch with the Manadient Van Diemen team.

Two years in the British F3 Championship in 1987-88, which included a victory with the works Reynard R+D team at Donington Park in his debut season, were the springboard to F3000.

Favre claimed pole position and second place on his maiden event in the final stepping stone to Formula 1 at Silverstone in 1989, but he was never able to recapture that form over the remainder of a truncated season with the GA Motorsport Lola squad.

He continued in F3000 with part-seasons in Japan with Team Noji and Leyton House in 1990 and then briefly raced in Indy Lights in the US, before being picked up by the Kremer Racing Honda sportscar team.

Favre made two starts in the Le Mans 24 Hours in Honda NSX GT1/GT2 cars in 1994-95. In 1995 he took 3rd place in the 24hrs of Spa Francorchamps driving a Honda Accord for Team VZM. In 1996 he was the lead driver for the factory-run Venturi 600LM in the BPR Global Endurance GT Series.

In 1998 he joined Thierry Tassin in driving the Honda factory team (ELR) Integra Type R in the 24hrs of Spa. In 1999, he returned to the 24hrs of Spa to drive a Honda Accord for team ELR. In last half of 1998, throughout 1999 and in the first half of 2000 he drove a Porsche 911 GT2 for various race teams in the FFSA/FIA GT Championship, 24hrs of Daytona and the 6 Hours of Vallelunga.

In 2000, he joined the factory Lister team to race in the FFSA/FIA GT Championship. He claimed podiums at the Hungaroring and Brno and continued to race for Lister until mid-2001. In mid-2001 he returned to driving Porsche GT2's, GT3-RS's and GT3-R's in the FFSA/FIA GT Championship.

In 2003-2005 he raced a Lucchini SR2000 in the FFSA/FIA Sportscar Championship and Le Mans Endurance Series.

Driver Racing Highlights

2003: 1st 6 Hours of Vallelunga

1995: 3rd 24hrs of Spa Francorchamps

1994: 16th 24hrs of Le Mans

1986: 2nd Formula Ford Festival

Racing career summary

Races entered: 118

Wins: 1

Podiums: 16

Pole positions: 5

Fastest laps: 7

Race win percentage: 0.8%

Podium percentage: 13.6%

Seasons Racing this Car:

1 - 1998 24hrs of Spa Francorchamps

Result: DNF due to engine issues

Qualified: 5th place

Miscellaneous Stats:

- Was odds favorite to win

- Held the fastest lap of the race

- Lead the race for 9 of the first 24hrs, the motor failed at hour 16 of 24 (8hrs remaining)

José Pedro Fontes

Driver Racing Highlights

2014: 1st Portuguese Sport Prototypes Championship

2013: 3rd Portuguese GT Championship

2012: 2nd Portuguese GT Championship

2012: 2nd Portuguese Championship GT3

2010: 3rd Portuguese GT Championship

2009: 1st Portuguese Touring Car Championship

1999: 1st Portuguese Touring Car Championship

1998: 1st Portuguese National Rally Championship

1997: 1st Formula Ford Portugal

Racing career summary

Races entered: 83

Wins: 20

Podiums: 49

Pole positions: 4

Fastest laps: 5

Race win percentage: 24.1%

Podium percentage: 59%

*incomplete stats

Rally career summary

Rallies: 3

Rally wins: 0

Rally podiums: 1

Class wins: 0

Class podiums: 1

Win percentage: 0%

Podium percentage: 33.3%

*incomplete stats

Seasons Racing this Car:

1 - 1999 Portuguese Touring Car Championship "Campeão Nacional de Super Produção" (8? races)

Result: 1st place in the championship

Alexandre Nogueira

Driver Racing Highlights

2014: 1st Portuguese (Historic) Legend Series "Campeonato Nacional Legends Cup"

Seasons Racing this Car:

1 - 2014 Portuguese (Historic) Legend Series "Campeonato Nacional Legends Cup"(6 races)

Result: 1nd place in the championship

*Also won two races in the 2015 series before retiring from racing

Modification Summary

Engine

Built and assembled by NBE (Neal Brown Engineering - elite Honda Motorsports engine builder)

Honda Type R B18C6 engine block (Badged as "Procar 2" with a Honda serial number of 0100017)

Honda Type R crankshaft

Honda Type R connecting rods with custom rod bolts

Honda Type R pistons (EDM/JDM compression - 11:1)

Honda Oil pump (possibly modified)

Honda Water pump

Honda Type R/GSR head gasket

Honda Type R cylinder head (port matched to intake manifold and dowel pins added for port alignment)

Honda Type R intake and exhaust valves

Honda Type R outer valve springs

Custom "stiffer" inner springs (for a higher 10,000 rpm limit)

Honda Type R valve guides

Custom Viton valve seals

Custom valve retainers

Honda Type R 98spec camshafts (possibly slightly modified within FIA specifications)

Custom (adjustable) camshaft gears anti-slip locking pins

Honda Type R timing belt

Honda Type R intake manifold (port matched to cylinder head within FIA specifications and dowel pins added for port alignment)

Honda Type R throttle body (port matched to intake manifold, throttle plate and shaft machined for decreased air turbulence)

Honda Type R fuel injectors and fuel rail

Honda Type R crank pulley (modified by adding a crank trigger wheel to the A/C ring)

Honda OBDI distributor (modified Honda Si-R unit)

Bosch Motorsports external ignition igniter/driver

Honda Type R sparkplug wires

NGK Racing sparkplugs (NGK Race for endurance and NGK laser iridium for sprints)

Custom modified Honda breather box "black box"

Honda Type R PCV system

ELR air/oil separator - breather box

ELR carbon fiber air box

ELR baffled oil pan

Mugen 4-1 exhaust manifold (originally was a NBE manifold, then Mugen 4-1, now is a Toda 4-2-1)

PSI Motorsports racing exhaust (2.75" - thin wall)

Honda Civic SiR "'half-size" single core radiator (ELR custom aluminum design was replaced with a Mishimoto X-line as a temporary replacement)

ELR/Foss-Tech (extra large) air-to-air oil cooler with ducting for radiator & oil cooler

Original Transmission

Hewland/Brena/WTI HRE "Honda Racing Europe" transmission

OE S80 transmission case

Hewland/Brena/WTI 1-5 straight cut "dog box" gearset

Hewland/Brena/WTI shift folks & modified selector box

Hewland Powerflow/WTI/Brena clutch LSD

ELR modified shift-linkage

AP Racing pressure plate

AP Racing clutch disc

AP Racing clutch master cylinder

AP Racing clutch line

Honda Type R axles (modified by ELR with stronger bearings, high temp grease, stronger and vented boots)

ELR/Foss-Tech carbon fiber transmission/inner CV cooling duct

New Transmission

Custom Quaife/DMRR sequential transmission

Modified Honda bell housing

Quaife outer housing

Quaife 1-5-R sequential straight cut gears with sequential selector/shift forks

Custom gear ratios to match the original Hewland/Brena/WTI ratios within 0.05% tolerance

Custom DMRR mechanical shift linkage and shift selector mechanism

Custom DMRR mechanical shifter (rally style)

Custom Geartronics transmission computer, gear position sensor and gear/trans temp display

Custom Quaife pneumatic shift selector

Custom Geartronics paddleshift system featuring carbon fiber paddles, air pump, air accumulator, solenoids, throttle blipper, motorsport wiring harness and closed-loop GCU transmission computer

Suspension/Brakes/Wheels/Tires

Custom Penske Racing 3-way struts w/ELR mounting hats (blueprinted and rebuilt by Anze Suspension)

H&R springs (front and rear)

AP Racing air jacks

Foss-Tech/ELR modified OE ITR power steering rack (rack limiters)

Foss-Tech modified OE engine mounts (spherical)

Foss-Tech modified suspension bushings (spherical)

Foss-Tech 3pc front anti-roll bar

Foss-Tech 3pc rear anti-roll bar

Foss-Tech modified front sub frame

Foss-Tech modified front upper arms

Foss-Tech modified rear upper arms

Foss-Tech modified rear trailing arms

Foss-Tech modified rear lower arms

Foss-Tech modified rear toe links

AP Racing CP3307 4-piston front calipers (modified by Foss-Tech/ELR)

AP Racing 2pc vented 330mm x 28mm front rotors

OE rear ITR calipers

OE rear ITR rotors

Pagid brake pads (front and rear)

AP Racing brake bias controller

ELR/Foss-Tech brake lines

ELR/Foss-Tech carbon fiber brake caliper, brake rotor/hat, outer CV cooling ducts

Tecnomagnesio Racing wheels 15x7 (magnesium)

ELR extended and quick spin wheel studs

ELR high-strength quick spin wheel nuts

ELR/Foss-tech modified wheel bearings (strengthened bearings/cage, high temp grease)

Dunlop/Michelin racing slicks (205 equivalent width)

Electronics

MBE 941v ECU w/custom ELR engine harness (chipset inspected & overhauled)

Stack 8100 dash (w/ lap beacon, wheel speed sensor, oil temp, water temp, fuel pressure)

SPA Technique electronic fire suppression system

Armtech battery isolator

OE glass power windows

OE power mirrors

OE windshield wipers

OE EDM headlights (leveling removed but interior switch remains)

OE EDM blinkers & side markers

OE EDM taillights

OE EDM fog light

ELR endurance lighting (HID low/high beams, door card lights, roof card light, antenna beacon)

Motorola 2-way radio communication

Modified windshield wiper washer system

AMB transponder

Premier Fuel Systems Kevlar fuel bladder (40L inside & 100L dual inside and outside)

Premier Fuel Systems fuel pumps (primary/secondary-backup)

Premier Fuel Systems dry-break fuel fill valve

Chassis/Body

Honda Race "body in white" chassis

Foss-Tech seamwelded chassis

Foss-Tech roll cage w/air jack provisions

OE metal body panels (hood, hatch, doors, roof, floor)

OE EDM metal fenders

OE EDM front and rear bumpers

OE glass (windshield, doors, rear quarter and hatch)

ELR/Foss-Tech carbon bumper brake ducts

Foss-Tech carbon fiber front bumper ducting for radiator and oil cooler

Foss-Tech modified steering column w/quick release

Spa Technique quick release steering wheel mount

Spa Technique/Alpha steering wheel

Foss-Tech carbon fiber dash vent covers

Foss-Tech carbon fiber covers

Foss-Tech carbon fiber center console cover

Foss-Tech carbon fiber emergency brake delete/switch panel

Foss-Tech carbon fiber door card covers

Foss-Tech carbon fiber/Nomex-aluminum honeycomb door bar crash structure

Foss-Tech carbon fiber rear quarter panel covers

Foss-Tech carbon fiber battery box

Foss-Tech carbon fiber/steel ballast box

Foss-Tech carbon fiber fuel cell/fuel fill cover

ELR pedals/dead foot cover

OMP King driver seat

OMP 6pt racing harness

Foss-Tech seat rails

Stand 21 window net

Sparco hood and hatch pins

Ongoing Resurrection Progress:

Completed items since taking delivery on June 20th, 2017:

6/20/2017

1. Took delivery of container at 4:38pm at a local warehouse

2. Unloaded container and transported car to shop

3. Added original specification engine oil (Motul 300V 10W40), transmission oil (Motul 300LS 75W90), coolant (Honda premixed), power steering system fluid (Honda) and brake fluid (Castrol SRF). At 7:30pm the motor fired to life.

4. Replaced old valve cover, valve cover seals, oil cap seal and valve cover hardware

6/21/2017

5. Added front and rear Honda Type R emblems (were missing)

6. Removed protective film and polished EDM headlights

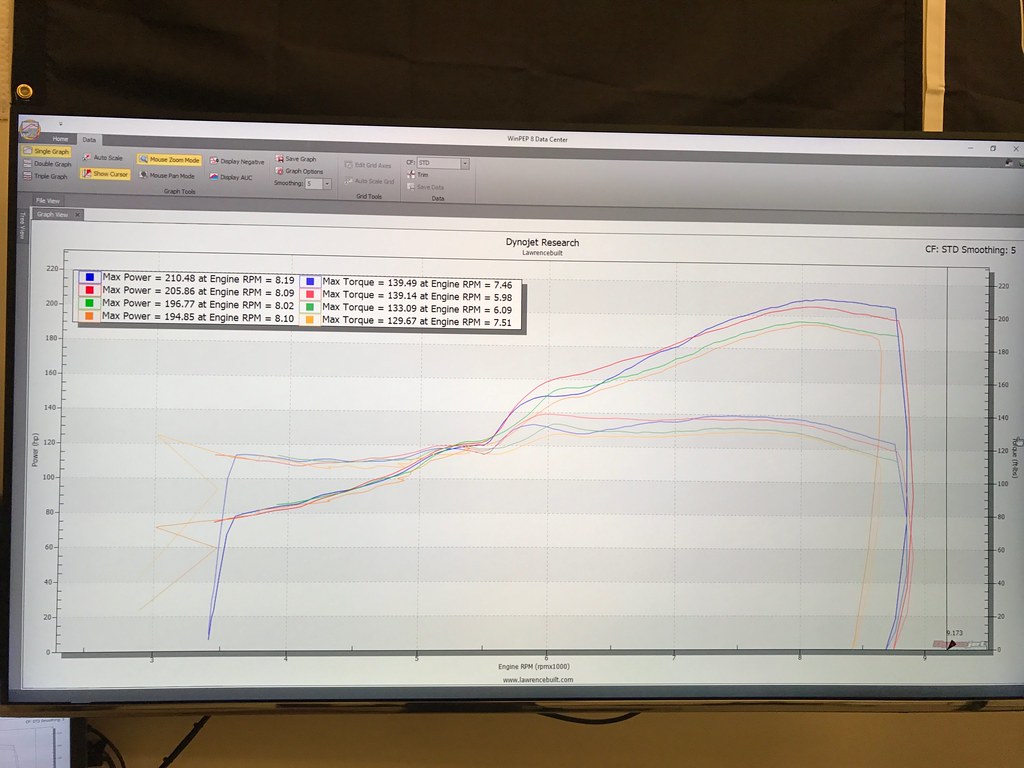

7. Dyno – Baseline test (195whp/130trq – Dynojet 248H)

8. Replaced lower rear subframe tie bar (was slightly bent and rusted)

9. Corner weight car – 2208lbs (no driver)

6/24/2017

10. Discovered broken rear wheel speed sensor – replacement ordered

11. Removed (original) protective tape from carbon fiber door cover and carbon fiber roll cage cover

12. Removed and modified front bumper & chin spoiler for missing carbon fiber brake ducts

6/25/2017

13. Installed new carbon fiber brake ducts & reattached existing brake ducting hoses

7/1/2017

14. Added window net to door (will likely remove to meet current safety standards)

15. Overhauled distributer (OE cap and rotor –uses external MBE coil/ignitor)

16. Overhauled rear fog light (reflector was broken – installed new parts where needed)

17. Replaced spark plugs (NGK race grade)

18. Replaced spark plug wires (OE)

19. Replaced VTEC solenoid (original unit was showing signs of surface rust)

7/3/2017

20. Added Honda decal to driver side carbon fiber roll cage cover

21. Lubricated door handles and window sliders

22. Replaced manual fire extinguisher bottle with (original design) electronic fire suppression bottle

23. Installed serial to USB connection for MBE ECU reprogramming and data logging

24. Reinstalled dash plaque (for driver name and sponsors during in car camera streaming)

7/4/2017

25. Dyno – Resolve air/fuel mixture inconsistencies (197whp/133trq – Dynojet 248H)

7/9/2017

26. Repaired & replaced Stack rear wheel speed sensor and sensor bracket

27. Replaced steering rack trim backing plate with a carbon fiber piece (previous unit was black painted aluminum and not original)

28. Removed air jack valve to determine appropriate coupling

7/15/2017

29. Installed speed bleeders and bleed brakes & clutch

30. Inspected existing fire suppression electronics and plumbing – everything tested fine

31. Installed adhesive aluminum and black vinyl chassis hole covers (to replace worn-out pieces)

32. Added new AMB Tranx 260 transponder to the original location/mounting holes on the chassis

7/22/2017 – 7/23/2017

33. Spent the weekend researching AiM and MBE ECU RS232 protocols and ordering necessary parts

7/29/2017

34. Added (temporary) florescent green film to door mirrors (to recreate original look)

35. Added ELR decals to door mirrors and wheels (to recreate original look)

36. Reinstalled original air jack valve and tested a modified nitrogen coupler (until the correct coupler is located)

37. Verified wiper squirter functionality – called “Lave Glace” on the center console and uses a self-contained system inside the car for quick refilling during pit stops

7/30/2017

38. Installed OE front tow hooks for ease of access when trailering

39. Installed (temporary) air bag delate tray while I get the original cover signed by ELR, Tassin, Fontes and Alexandre

40. Alignment inspected by Graham – zeroed out toe (had lots of front and rear toe out)

7/31/2017

41. Track Day – Laguna Seca w/NCRC – On Track Observations summary coming soon!

8/5/2017 – 8/6/2017

42. Traveling for work

8/12/2017

43. Installed AiM Solo DL w/ RS232 connection to MBE ECU (for advanced data logging, driver display and satellite based lap timing)

44. Removed and try remounting seat. Discovered loose rear bolts are causing seat movement and existing mounts cannot be adjusted enough. Ordered new brackets

45. Cleaned and restored suede steering wheel with Sonax solution

8/19/2017

46. Removed and replaced cylinder head & cams (using a spare/alternate)

47. Dyno – Retune for new top end (206whp/139trq – Dynojet 248H)

8/24/2017

48. Installed new 4-2-1 Toda style exhaust manifold (removed original 4-1 Mugen)

49. Dyno – New exhaust manifold leaned out AFR, retuned where necessary (210whp/139trq)

50. Removed OE radiator fan and installed new "slim" fan & shroud

51. Tested new (original spec - Walther Prazision) air jack coupler and verified normal leak-free operation

52. Discovered passenger rear brake was stuck, upon inspection I found the inner brake pad alignment notch was misaligned causing the pad to make uneven contact with the rotor. This would explain the minor brake stability issue I noticed while on the track. New rear rotors and pads (original ELR spec) are on order.

8/26/2017 - 8/27/2017

53. Worked on other race car

9/2/2017 - 9/3/2017

54. Finished rebuilding the motor and transmission on the daily driver

9/9/2017 - 9/10/2017

55. Installed and tuned motor for the daily driver

9/16/2017 - 9/17/2017

56. Repaired carbon ducting for oil cooler (side plate was previously damaged – replaced with a new piece)

57. Overnighted MBE Systems ECU to Europe for chipset and software update/upgrade

58. Replaced ELR air filter with a new element

59. Attempted to remount seat without success (head protection is interfering with roll cage - will need to try an alternate solution such as using different brackets or trying a different seat design)

9/23/2017 - 9/24/2017

60. Removed original and faulty (AP Racing) clutch master cylinder to get the part number and order a replacement unit.

61. Installed a new smaller and lighter battery (10lb weight reduction)

62. Refinished ELR clutch master cylinder adapter plate

9/30/2017 - 10/1/2017

63. Installed (overhauled) MBE Systems ECU and verified everything works as expected. Will require a retune but it's working very well thus far.

64. Installed a new clutch master cylinder & firewall adapter bracket

65. Bleed clutch master cylinder

66. Removed ELR clutch pedal cover to minimize change of clutch pedal bind while I adjust the clutch throw

67. Test drove car and verified clutch master cylinder is working

68. Discovered clutch will not disengage even after adjusting the clutch master cylinder. The clutch disk like broke a spring and will need to be replaced

69. Ordered a new clutch pressure plate, clutch disk, flywheel, pilot bearing, throw-out bearing, clutch slave, clutch fork and clutch fork spring

9/30/2017 - 10/1/2017

70. Removed transmission clutch and flywheel

71. Discovered the release bearing and clutch are AP Racing units and the flywheel is a custom modified OE unit. The clutch is a single plate, one piece aluminum stepped design pressure plate with a 4-puck/paddle rigid disc. The flywheel was modified to be a stepped design and have mounting studs machined/welded onto it with anti-rattle springs. The entire setup it quite impressive, especially by 1998 standards. Also the entire assembly weight is roughly 21lbs, about the same as a standard "steel sprung" clutch with a lightweight flywheel.

72. Discovered the passenger side axle was stuck inside the differential. Will need to repair transmission housing and replace both drive shafts

73. Discovered the Hewland gear set is actually a Brena/WTI gear set in a modified Hewland case

74. Discovered the transmission casing has extensive modifications for clearance and improved oil flow

75. Discovered the transmission case has HEW1 and HRC-012 (serial number) engraved in the case

76. Discovered that all the suspension bolts and nuts were changed to a higher grade and same size (likely for rapid pit work)

77. Discovered the Penske suspension has ELR engraving on struts and springs

78. Shipped transmission case to machine shop for repair

79. Ordered new "road race" drive shafts

10/14/2017 - 10/15/2017

80. Removed and shipped Penske suspension for full rebuild/overhaul

10/21/2017 - 10/22/2017

Took the weekend off for non-racecar related work

10/28/2017 - 10/29/2017

Waiting on parts to arrive...

11/4/2017 - 11/5/2017

Waiting on parts to arrive...

11/11/2017 - 11/12/2017

Was at the Creventic/Hankook 24H COTA event with Marc from ELR (who built and oversaw this car) and Mark (who built, raced and oversaw my yellow race car)

11/18/2017 - 11/19/2017

Worked on daily driver

11/25/2017 - 11/26/2017

Worked on daily driver

12/2/2017 - 12/3/2017

Worked on daily driver

12/9/2017 - 12/10/2017

Removed leaky and worn-out front brake calipers for blueprinting and rebuild (by Essex/AP Racing)

12/16/2017 - 12/17/2017

Holiday stuff

12/23/2017 - 12/24/2017

Holiday stuff

12/30/2017 - 12/31/2017

Installed new clutch release bearing, clutch slave, clutch fork and clutch fork spring

Installed new pilot bearing, flywheel and clutch

Installed new custom sequential transmission

1/6/2018 - 1/7/2018

Installed blueprinted and rebuilt Penske suspension (thank you Anze)

Installed new Road Race "vented" axles

Installed shift mechanism & gear display

1/13/2018 - 1/14/2018

Installed blueprinted and rebuilt front brake calipers (thank you Essex)

Installed new front (Pagid RS-29) brake pads (will burnish after the rears are installed)

Full flush and bleed entire brake system

Replaced failing front lower ball joint (driver side)

1/20/2018 - 1/21/2018

Installed transmission wiring harness, ECU and sensors

Added break-in fluid and finally got the transmission running

Calibrated the mechanical shift-linkage and set the shifter stops

Broke-in the clutch LSD (driving in a figure 8 for about an hour)

Verified ignition cut functionality and initial transmission (electronic) settings

Did a baseline dyno pull and verified the air/fuel ratio needed to be adjusted at partial throttle due to the new chipset in the MBE ECU. Power is 212whp & 142 trq.

Wasn't able to fine tune the transmission ECU or verify WOT ignition cut because I ran out of gas on the dyno. Oops.

Also discovered the power steering system is starting to fail as it overflowed on the dyno due to fluid starting to foam. I also noticed this happened on the track earlier last year. Likely it's a result of a failing power steering pump (you can also hear it whine while idling). New parts ordered, the entire system will be overhauled or replaced as needed.

1/27/2018 - 1/28/2018

No progress - was tied up all weekend with getting a new pit dug and cement poured for a new chassis lift (Bendpak SP-7XF)

2/3/2018 - 2/4/2018

No progress - cleaning shop & wash hosed off both race cars

2/10/2018 - 2/11/2018

No progress - family stuff

2/17/2018 - 2/19/2018

Installed new OMP carbon seat (WRC-R - carbon core - 10lb weight reduction over the old seat)

Installed FIA fixed mounted and light weight seat bracket

Adjusted harness for new seat location

Reinstalled center console and switch panel

Cleaned up ECU wiring

2/24/2018 - 2/25/2018

Not much progress - spent Sat working on the Lawrencebuilt drag car

Installed the carbon fiber lid for the ballast tray

Secured the shift boot to the sequential shift lever

3/3/2018 - 3/4/2018

No major progress - had to work on tax stuff

Installed a carbon replacement cowl cover and relocated the battery cut-off button to the original location (next to the fire suppression system button). The original cowl cover was heavily worn and the new carbon cover limits the amount of engine bay air that can get pushed into the cabin.

3/10/2018 - 3/11/2018

Ryan Conley came over for a visit and guess what? #ryanconley

I took the car for a quick drive around the parking lot and discovered the fuel drain valve was leaking. I put the car on the (new) lift and found the value o-rings have failed which allowed pressurized fuel to leak from the open/close knob. A new FIA approved Staubli SPT valve will be installed next weekend. Thanks Ryan!

I also replaced the pad holder bolt on both from calipers. After the caliper rebuild I needed to replace both bolts with a identical unit.

3/17/18 - 3/18/18

Removed leaky fuel drain valve and replacing with a -6AN plug until the Staubli valve arrives

Installed new rear rotors and modified Pagid RS4-2 rear brake pads (modified to HRE "Honda Racing Europe" specifications) - thank you Jack Myers of Myers Competition Products! A+ work as always

Disassembled spare power steering pump for rebuild. I'll first start with rebuilding the spare pump. If that works then I may or may not replace the other parts at this time.

3/24/18 - 3/25/18

Rebuilt the power steering pump (will not use at this time)

Removed the power steering system hoses/lines

3/30/18 - 4/1/18

Installed Stäubli (dry break) fuel drain valve

Installed new power steering pump

Installed new power steering pressure line

Installed new power steering low pressure lines

Installed new power steering reservoir & bracket

4/7/18 - 4/8/18

Installed a new power steering cooler unit inside the oil cooler ducting and bleed the entire system

Adjusted the partial throttle compensation and 3D fuel maps

Tested full throttle sequential shifting at 9k rpms. Wow!

4/14/18 - 4/15/18

Installed new front & rear upper camber arms & spherical mounts

Installed new rear toe links

Installed new radiator and hoses

Installed load cell on shifter rod

4/21/18 - 4/22/18

Corner weighted

Aligned chassis

4/21/18 - 4/29/18

Install AiM EVO5 w/GS display for increased data telemetry

Resume dyno tuning & possibly install an adjustable fuel pressure regulator

5/27/18

NCRC Track Day @ Laguna Seca!

To-Do items over the next 2-5 months

Replace fuel pumps, filters and inspect hoses

Order OE spec Dunlop racing slicks and mount on newly refinished wheels

Send original fuel bladder to Premier Fuel Systems for replacement

Strip/repaint exterior and return exterior to the original livery before Expo 18 (West Coast)

Overhaul and replace original brake lines/bias controller

Install new front LCA arms

Dyno Tuning Progress

Yellow/Orange = Baseline, no changes outside of adding fluids and gas

Green = Retuned AFR and timing

Red = Retuned with a spare/alternate cylinder head and cams

Blue = Retuned after replacing the original 4-1 Mugen exhaust manifold with a 4-2-1 Toda style exhaust manifold

Takeaways: While the Toda style header loses a decent amount of power/torque between 5800-6800rpms, the engine for the most part stays above 6800rpms on track. We'll either do some additional tuning and/or will try a few different exhaust manifold setups to find the sweet spot. Right now it's good enough considering it's making 10-20whp more then the last time it was on track (the green curve).

Pictures

Belgium - circa 1998 - Lease Plan Belgian Procar Series

Portugal - circa 1999 - Portuguese Touring Car Series (Campeonato Nacional de Velocidade)

Portugal - circa 2014/2015 - Portuguese (Historic) Legend Series (Campeonato Nacional Legends Cup)

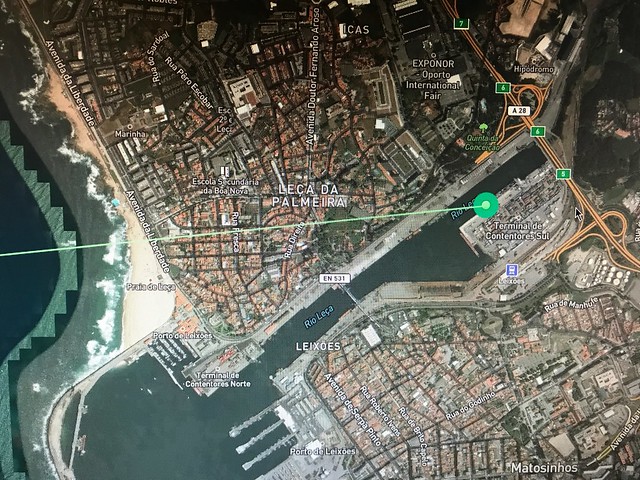

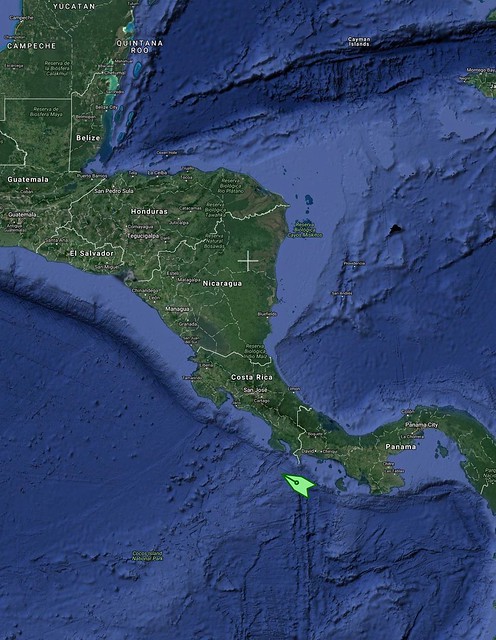

Portugal - Getting loaded into the container and headed for the USA - April 21st, 2017

California, USA - unloading container - June 20th, 2017 - two months later

California, USA - present day (in progress)

Laguna Seca - July 31st, 2017(in progress)

In Progress

Videos

History of the 24hr of Spa Francorchamps

(first 8mins are of the events 50yr history and the last 30mins of actual car racing with this car)

https://youtu.be/TonvPBICTaw

Historical racing footage- Compilation of various events from the 1998 Belgian Procar Series

(same link as above but starts at the 7:42 mark)

https://youtu.be/TonvPBICTaw?t=7m42s

First time driving the car

Laguna Seca - July 31st, 2017

(Had to use partial throttle going up the hill (turns 5-6) due to the 90db sound limit. The sound booth was getting me at 98db at full throttle)

https://youtu.be/OS3wymSPgjE

Same event as above but are clips taken from pit row:

Laguna Seca - July 31st, 2017

https://youtu.be/1TkeO__YbIA

Tuning the car on the dyno:

Front/engine bay

https://youtu.be/vXHepLtPCds

Rear

https://youtu.be/-5DbYxALzd4

Inside

https://youtu.be/kQTNj4acbFE

Testing the air jacks:

https://youtu.be/nB3XCN87COs